When we think of X-rays, we immediately think of images of our bodies. We know that X-rays can reveal a broken bone for example, but they can also give us information about what is happening inside inanimate objects.

Chairs are particularly interesting because, unlike static furniture like tables and cabinets, they must submit to stress from all directions: they are sat on, rocked back and forth, picked up, and dragged around. This portability has led to many different solutions for joints that we often cannot see from the outside.

Let’s consider the example of this 1720 Massachusetts side chair.

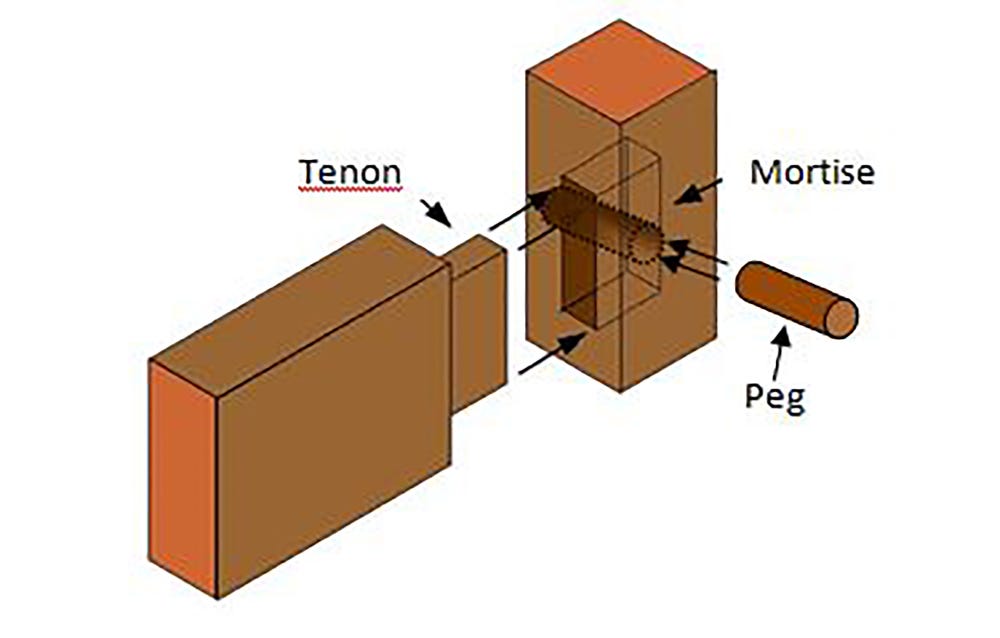

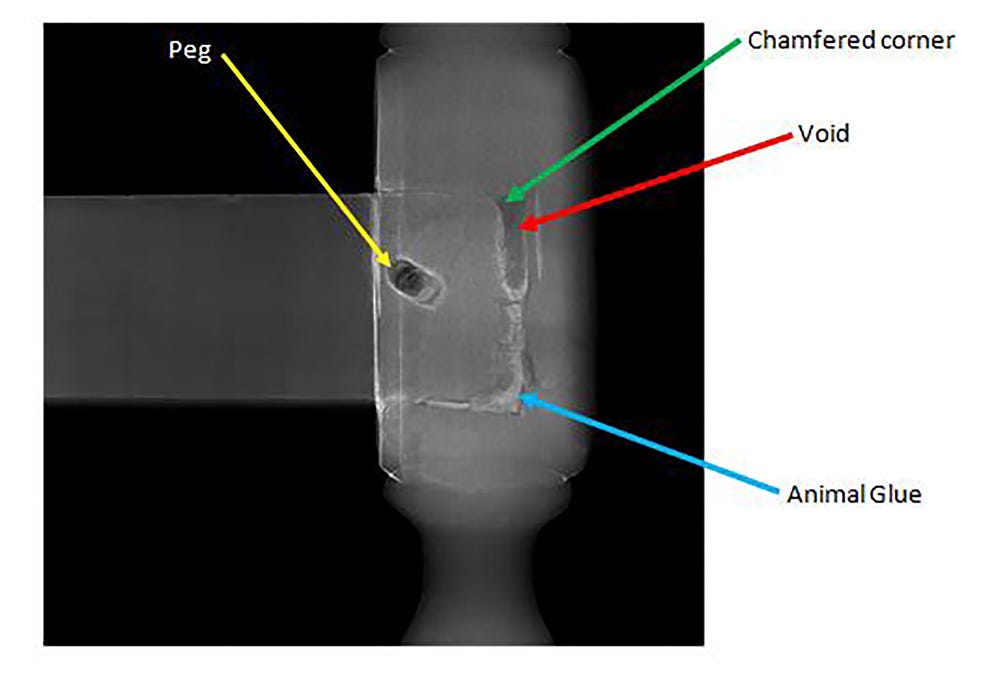

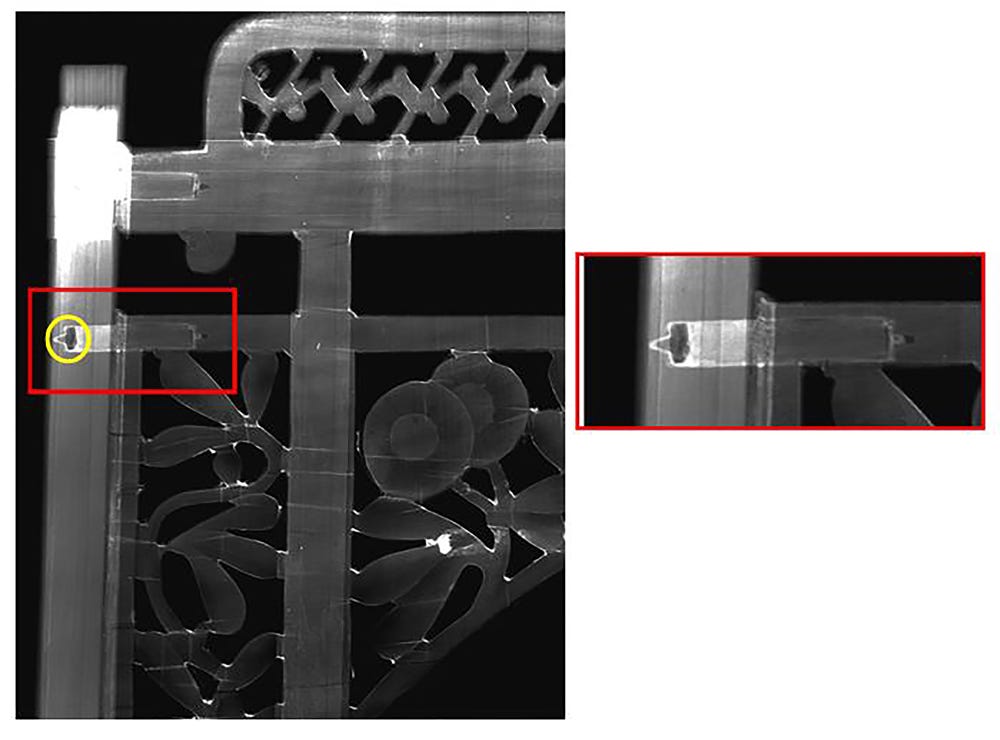

To its right you see the joint, circled in red, between the left front leg and left stretcher (the horizontal piece of wood connecting the front and back legs). The X-ray below reveals the interior of the joint. This type of joint is very standard in wooden construction. A hole (mortise) chopped or machined into one piece of timber receives a tongue (tenon) cut on the end of the second piece so that it fits exactly into the mortise. Often, these joints were given extra stability with a peg inserted through the joint to lock it in place. The diagram below illustrates a pegged mortise and tenon joint.

Going back to the photos of the chair, we can start to decipher the inner workings of this joint. The red arrow shows the void left in the mortise, which was chopped out a bit too deeply. The tenon of the horizontal element doesn’t quite reach the end. Some of this space has been filled with animal glue, shown by the blue arrow. The corners of the tenon have been nicely chamfered for ease of entry, as shown by the green arrow. Finally, the peg is shown by the yellow arrow. This peg is the only information about the joint that is visible from the exterior.

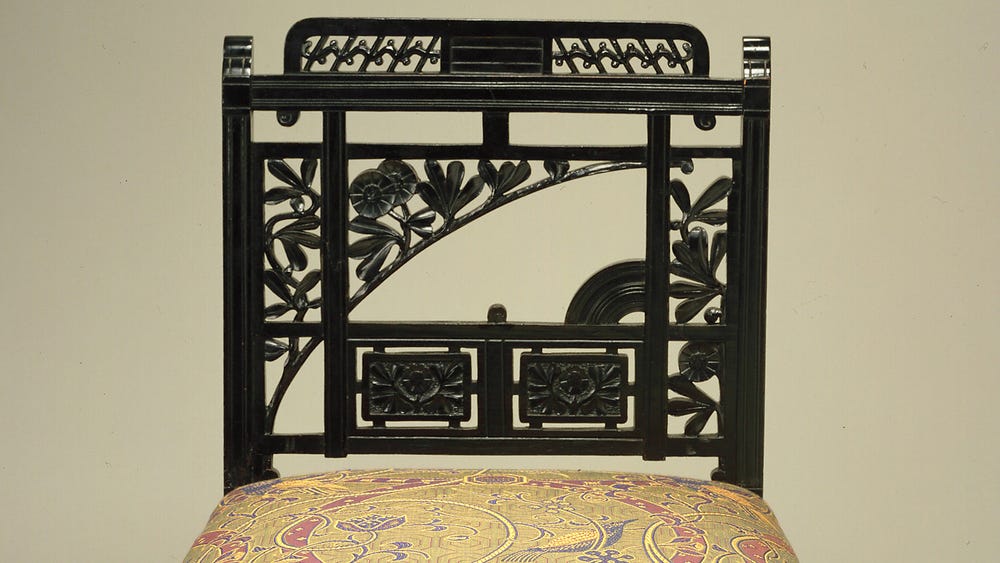

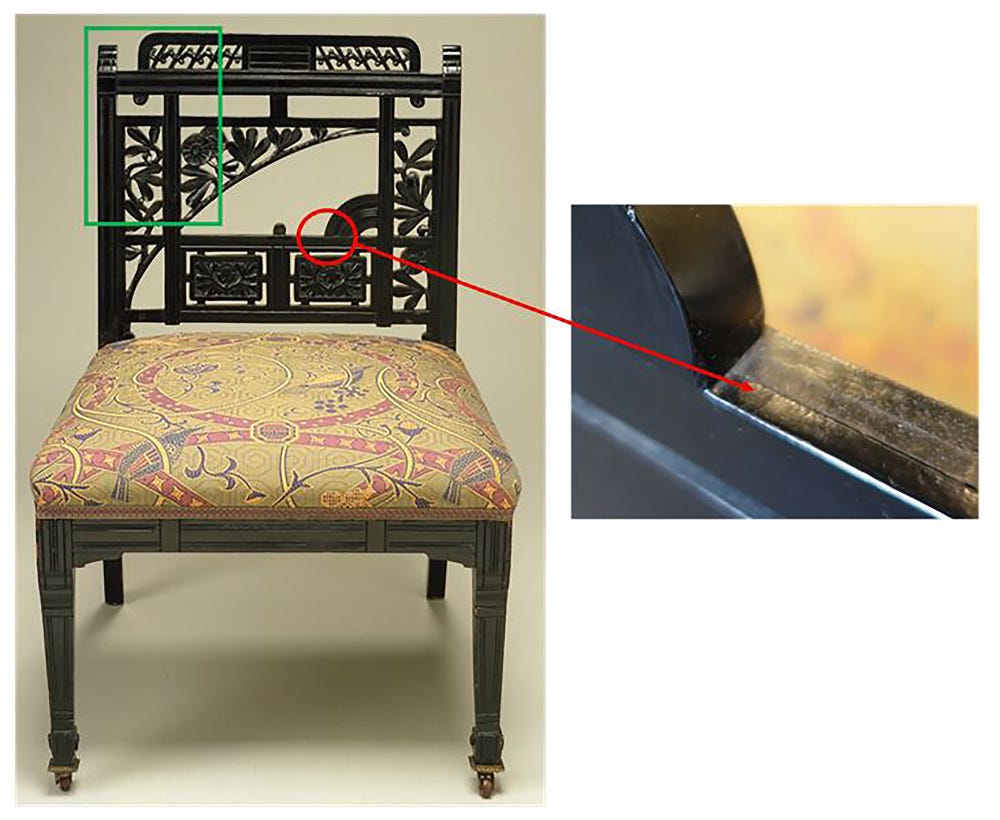

Of course, over time and with technology, many other innovative solutions for joining pieces of wood were developed. This chair, made in 1880 by the Herter Brothers, a New York-based furniture and interior design firm, highlights some of these techniques.

From the exterior, hints of more modern technology are already visible. For example, the delicate open-work back is not carved from solid stock, but instead made from an early form of plywood. Here, three thin layers of wood have been glued together, with alternating grain directions. This layering allowed the fine shapes to be cut and carved without causing breakage. The area of the detail showing the ply is circled in red (the photo was taken from the back).

The X-ray of the back of the chair (taken from the area within the green rectangle) reveals a modern update on the traditional mortise and tenon joint. The red rectangle shows a dowelled mortise and tenon joint. Here, mortises have been drilled, instead of hand-carved, into both pieces of wood. A mass-produced wooden dowel, or peg, has been inserted into both holes to bridge the pieces. The point of the drill bit (circled in yellow) is visible at ends of the mortises. Machined joints making use of pre-fabricated items such as dowels and biscuits greatly sped up the process of joining.

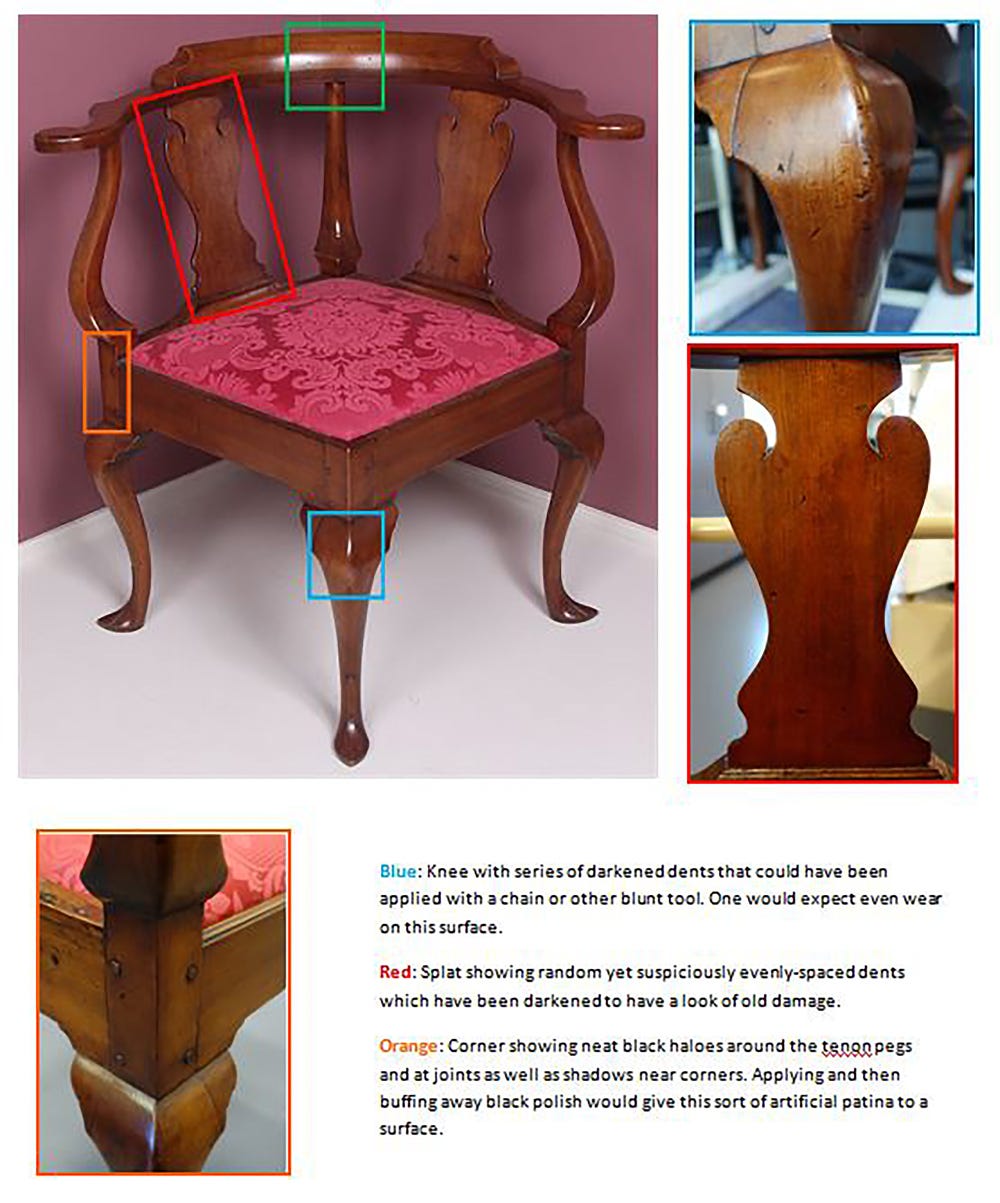

Fakes can also be unmasked using X-rays. Take, for example, the chair pictured here. It was sold as a period Philadelphia corner chair from 1750, just thirty years after the Massachusetts side chair above. Experts later raised questions about the chair’s authenticity based on its lack of a natural-looking patina (another word for accumulated layers of finish, wax, and dirt). A look of age seems to have been artificially added by deliberately damaging the surface with marks that do not correspond to normal use. These marks, along with other edges, have been enhanced by what appears to be black wax or polish smeared on and then buffed off to leave dark, old-looking material in these areas. Examples of these characteristics have been highlighted below.

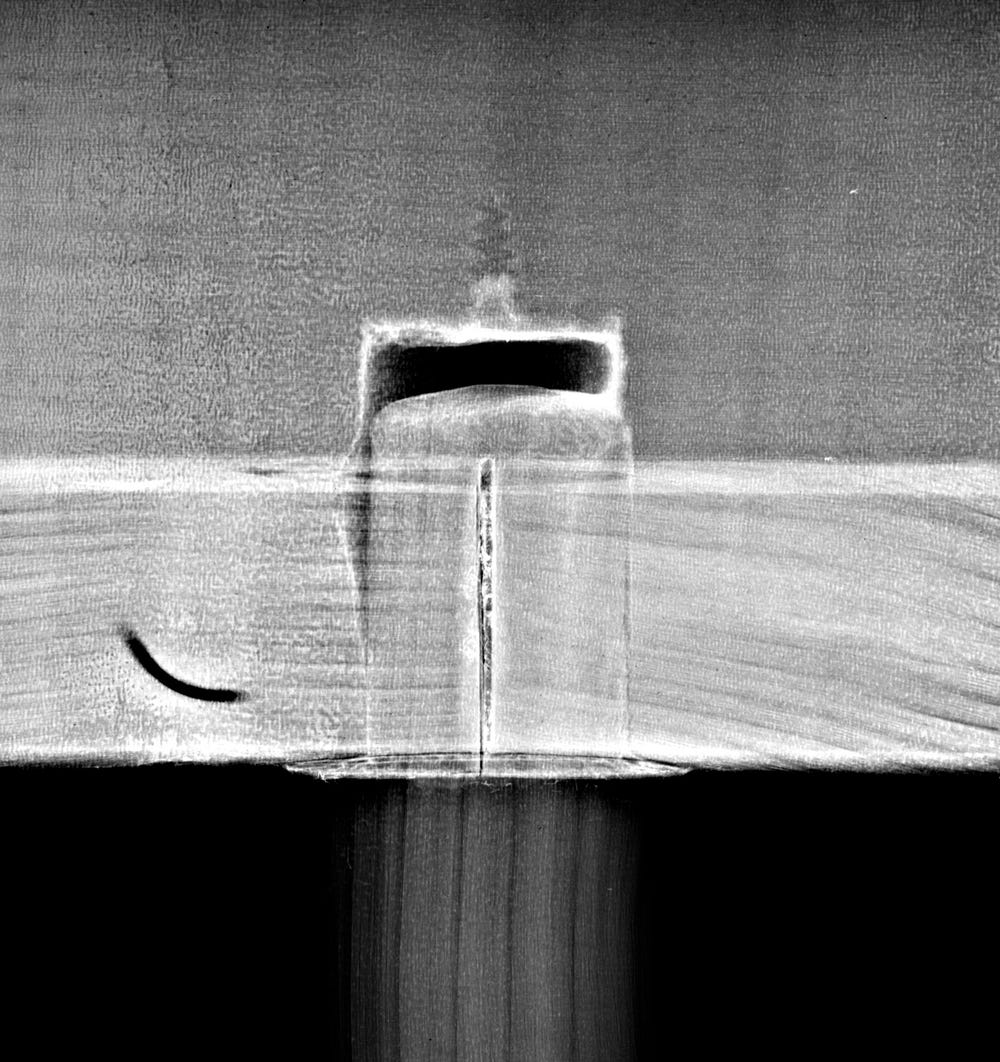

These observations on their own, however, are not quite enough to make any firm conclusions. A determined dealer can find an explanation for just about anything. In this case, it was an X-ray of the joint between the back stile and crest rail that revealed the true nature of this chair.

Upon first glance, the mortise has much more in common with the late-19th century Herter Brothers chair we just examined than the contemporary Massachusetts side chair described above. The profile of the mortise is perfectly square, and at its bottom, we see the swirled end of a drill bit. Around 1750, you would still expect chopped or carved mortises. (Hand) drills were not commonly used until a full century later. In fact, this particular profile is consistent with a Russell Jennings bit, which was not patented until 1855.

This last bit of evidence proves that the entirety of the chair could not have been manufactured in 1750. It is, at the very least, a 19th century pastiche. The cabinetmaker who made it could not have guessed that high-tech, non-destructive forensic examination of his creation using invisible rays would reveal his trickery!

Catherine Coueignoux is an object conservator with an expertise in furniture conservation.